Leading global provider of mission critical air and gas handling products, technologies and services, Howden, has agreed a contract with Precision Fabricating & Cleaning to provide a diaphragm compressor package for the innovative ITER fusion project.

ITER is an ambitious energy project to build the world’s largest tokamak, which is a magnetic fusion device designed to prove the feasibility of fusion as a large-scale and carbon-free source of energy. A collaboration between 35 nations, the experimental project aims to advance fusion science in order to develop fusion power plants in the future.

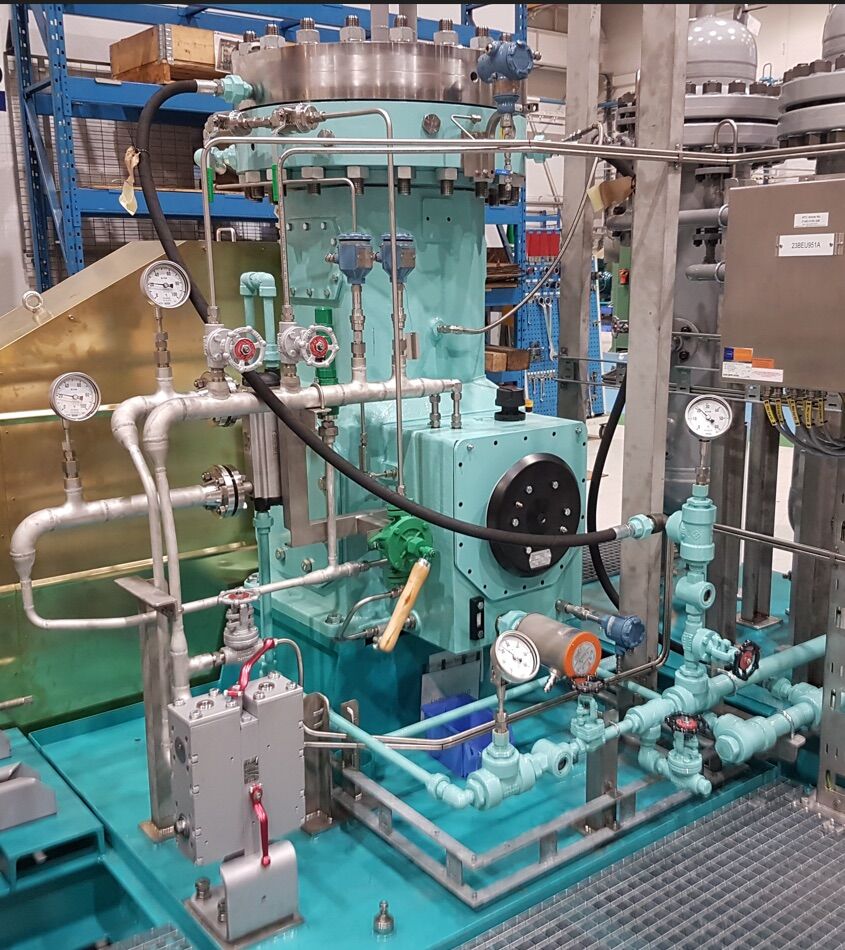

Precision Fabricating & Cleaning commissioned Howden to supply a diaphragm compressor package for the tokamak. Although the tokamak itself is experimental technology, Howden’s experience across energy applications, including nuclear, provided the necessary expertise to deliver a technically efficient and reliable product that met project requirements.

Salah Mahdy, Global Director of Renewable Hydrogen at Howden, said: “The ITER project is an incredibly innovative experiment being carried out by multiple nations around the world. If successful, it could allow for the development of fusion power plants and play a significant role in the energy transition.

“Howden has supported the energy transition for many years, working with key customers to advance new technologies, particularly in the hydrogen field. This is an exciting project to be a part of and we are confident our compressor package will deliver the results required while the team works to achieve its goals.”

Howden delivers reliable compression solutions to a range of highly diversified end-markets and geographies. Developing innovative solutions for its customers, Howden optimises the availability, reliability and installation footprint to reduce the total cost of ownership of customers’ operations.

In the energy transition space, Howden has played a significant role in providing reliable hydrogen compression solutions to a number of projects around the world. These major milestone developments include supplying hydrogen compression solutions for the world’s largest hydrogen refuelling station in China; the world’s first green steel plant in Sweden; and the world’s first climate neutral fuel (eFuel) plant in Chile.