To demonstrate to the Environment Agency that the Thetford power station is performing within the conditions of its environmental permit

a multiparameter emissions monitor is being used.

However, data from the analyser, which was supplied by Quantitech, also performs an important role in helping to manage the plant, which is operated by Energy Power Resources. Andrew Corbyn, Thetford plant manager, explains: “Individual gas readings are displayed in almost real-time in the control room which enables our staff to respond quickly to the changes resulting from variations in our feedstock. This ability to continually adjust the process ensures that we operate the plant efficiently; generating the maximum amount of renewable energy while maintaining a good clean burn.”

The plant has a net installed capacity of 38.5MW and generates enough electricity for many thousands of homes. It is the largest poultry litter fuelled power station plant in Europe. All of the plant’s feedstock is biomass and comes from sustainable sources and in comparison with a coal-fired power station, the plant makes a significant contribution to the fight against global warming.

Around 40,000 tonnes of combustion ashes generated by the plant are marketed and sold as Fibrophos fertilizer, which is high in phosphate, potash and trace elements.

Heat from the combustion process is used to generate steam which drives a turbine that generates power exported to the local distribution network. Emissions from the plant are effectively abated through combustion control. However, the plant also operates a bag filter system for particulates and injects bicarbonate into the waste gas stream to remove acid gases such as HCl and H2SO4.

Emissions monitoring

Thetford Power Station operates under an environmental permit and as such the plant has to provide the Environment Agency with continuous monitoring data including half hour and daily averages for HCl, SO2 and TOC (total organic compounds). Monitoring data for CO, NOx and dust are also reported to the Agency.

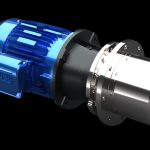

Quantitech has installed an MCERTS approved Gasmet fourier transform infrared (FTIR) analyser and an MCERTS approved 3006 flame ionisation detector (FID) to continuously monitor all of the gaseous emissions.

Thetford operates a second FTIR analyser to ensure that there is no possibility of downtime. Kevin Williams, EPR group environmental manager, said: “We originally purchased the portable Gasmet DX4000 analysers as an emergency back-up unit, but the core measurement components of a DX4000 are exactly the same as the Gasmet CEMS, so it made sense to run both analysers simultaneously so that we always had a ‘hot’ back-up.”

The Gasmet CEMS employs an FTIR spectrometer to obtain infrared spectra from the exhaust gas by first collecting an ‘interferogram’ of the sample signal with an interferometer, which measures all infrared frequencies simultaneously to produce a spectrum from which qualitative and quantitative data are produced.

Gasmet FTIR technology was chosen for the plant because of its ability to monitor multiple gases simultaneously. Richard Bloomfield, operations team leader said: “The system has performed well, with very little maintenance required. Zero point calibration with nitrogen (background) just takes a few minutes each day and is fully automated. Water vapour calibration is conducted at least once per year, but under normal circumstances no other calibration is necessary.

“The Gasmet analysers are our eyes and ears; providing us with almost real-time information on conditions inside the combustion chamber. We have a display in the control room that provides recent trends in addition to the live data, so that we can take steps to ensure optimal combustion efficiency, while maintaining compliance with our emission limits.”

There are a number of ‘tools’ with which the combustion process can be managed. For example, it is possible to adjust the feed rate, the distribution on the grate, the grate speed and air flow from below (primary air) and from above (secondary air).

Commenting on the solution, Nick Gooden, who is responsible for running the instrumentation, said: “If the CEMS starts to report unusual figures, it is tempting to blame the analyser, but with the benefit of a duplicate FTIR system, we usually find that the second analyser is reading exactly the same, which helps us to identify the true cause of the issue.”