As much as we don’t want to admit it, modern temperature sensing systems are often the children of compromise. They are usually created after most of design work for the underlying equipment is complete, which means thermal systems must conform to the constraints of the underlying system. As a result, issues not at the forefront of a manufacturer’s mind may emerge. In this article, Jeremy Ohse, staff engineer at industrial heating technology manufacturer Watlow, explains how thermocouples can eliminate these compromises.

Sometimes, budget can limit a temperature sensing system’s potential and companies cannot always get the sensor or heater density they desire. It’s possible to save a lot of money by reducing the number of sensors, but this comes at a cost of losing a complete picture of the entire system.

Space also plays a role. Heaters and sensors take up space, and the wiring that connects them grows with each addition to the system. This ultimately requires more space, which may not be possible in all setups. Companies respond to this issue by wiring their heaters in series, reducing the wiring and space requirements. However, doing so risks removing the ability to fine-tune the system, which creates implications for effectiveness and efficiency.

The danger of these compromises is that they can impact daily operations in ways that are not always apparent at first glance, but rather living in a manufacturer’s blind spot. Companies might be running their heaters too much or too little, with product or quality implications without being aware.

Thermocouple heater (TCH) control

But what if we could live in a world where there is no need to compromise? Creative use of an older technology can make this possible.

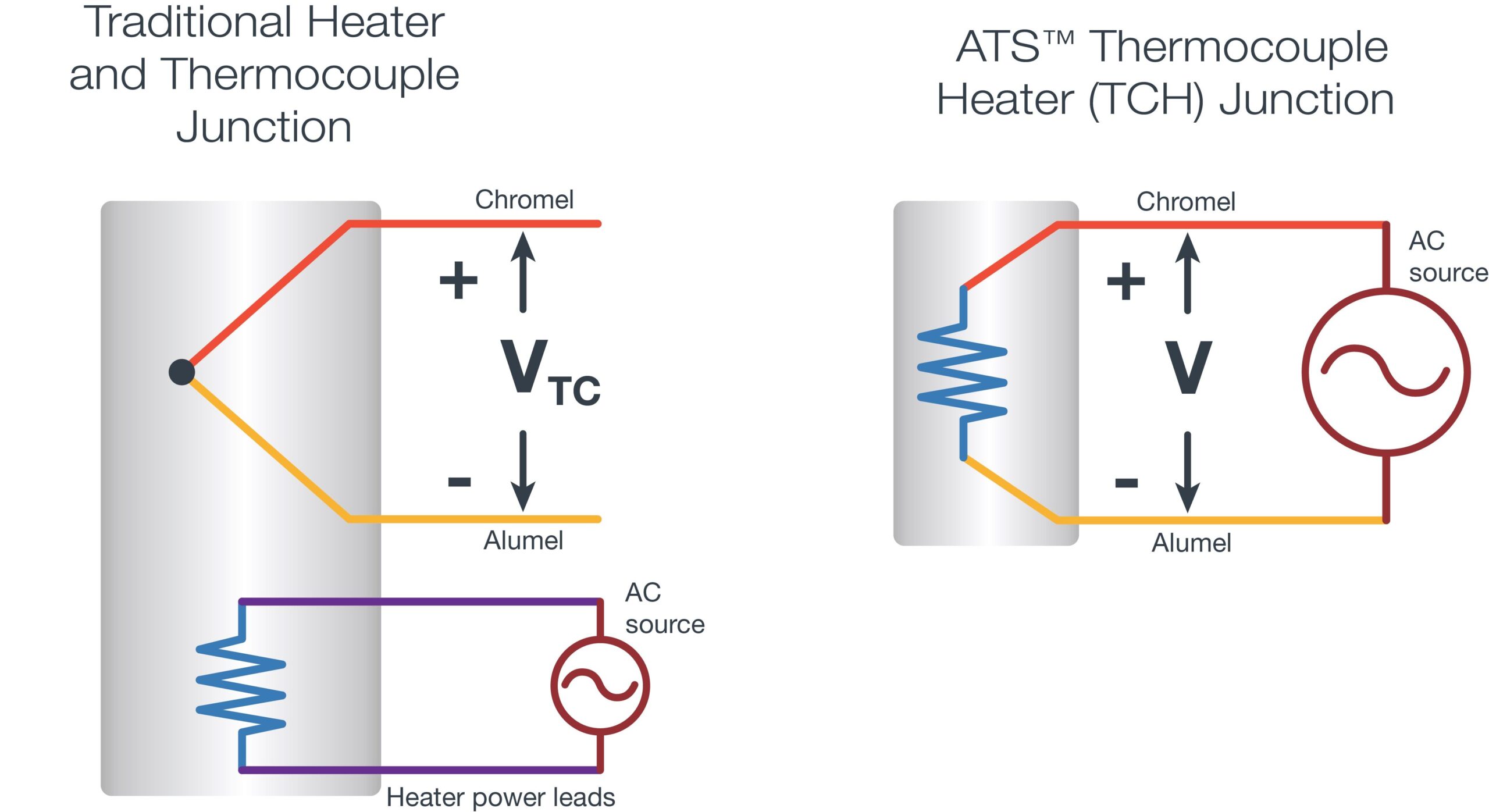

Thermocouples are nothing new. Essentially, they consist of two dissimilar conductors forming an electrical junction. The setup is extremely sensitive to temperature changes, which can be measured by the change in voltage that flows through the thermocouple. Watlow is a manufacturer of temperature and process controllers, which has developed thermocouple heater (TCH) control that is significant due to its placement. When integrated into a heater’s power leads, it can provide temperature sensing without needing a discrete sensor.

Without a discrete sensor, there is little need for sensor wires to be run into the system, which saves on cost and space. Plus, they are mounted close or even within the heaters, providing precise measurements in specific locations to present the most complete view of a system’s performance.

How TCH fits into a thermal system

A new temperature sensor is only a small part of the change that is needed in industrial temperature sensing. More advances are necessary to take advantage of the TCH’s space-saving design and in-line temperature sensing capabilities.

For example, Watlow’s Adaptive Thermal Systems (ATS) is an edge-to-edge thermal management suite that include the TCH. While the harness that holds wiring for heaters and sensors is not always the first thing we think of when we think of innovation, the harness in ATS is worth highlighting. Featuring a standardised connector, the harness makes it easy to wire different heaters into the same system, and halves the number of connections required.

It’s important to stress that the right solution for an industrial temperature sensor system is never an “off-the-shelf” solution. But the wrong custom solution can leave you with blind spots that create significant problems within the application. TCH and ATS enhance each other’s value when combined. As a result, this provides incredible value without breaking the bank and forcing companies to compromise on features that can lead to detrimental issues down the line.