With certain products, food manufacturers can realise great benefits from using dual energy x-ray detection, especially when paired with advanced photon counting technology. Mike Pipe, Head of Product Inspection of Mettler-Toledo Product Inspection, explains how these technologies together can significantly improve both contaminant detection accuracy and overall business performance.

The detection of foreign body contaminants is part of the critical quality assurance process to improve food safety standards. X-ray inspection has long been a key technology in this process, but there are different types of x-ray detection with which food manufacturers can inspect their products, depending upon the nature of the application.

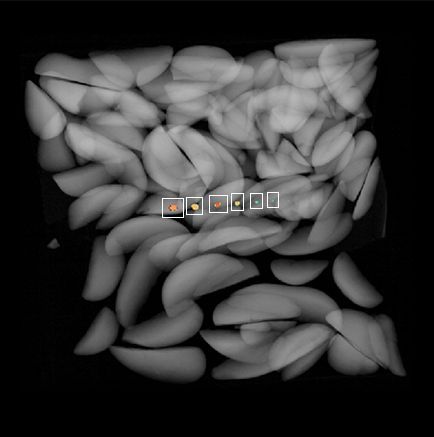

The three images illustrate different x-ray imaging techniques: on the left, we have Single Energy imaging, which captures x-ray data at one energy level; in the center, Dual Energy imaging, which utilises two distinct energy levels for enhanced contrast and detail; and on the right, Photon Counting Dual Energy imaging, which counts individual photons to provide even greater precision and clarity in the resulting images.

Traditionally, manufacturers have used single energy x-ray detectors, but dual energy technology is becoming more commonplace, and is more powerful, effective, and easy to use than ever before. It works using the concept of ‘material discrimination’, with dual x-ray beams of different energy able to identify materials of different densities. Advances in detection sensitivity mean that dual energy x-ray is now even more discerning, allowing ever-smaller contaminants to be detected in a wider range of applications.

Applications Suited to Dual Energy X-Ray

But what are the applications in which dual energy x-ray excels compared to the more commonplace single energy detection systems? In simple terms, there are two key aspects of a product that make it suitable for inspection by dual energy x-ray. The first is where there is a large degree of overlap within the package, or where there are variations in thickness. Examples of the types of packs where products overlap include packs of pasta, rice, nuts, and frozen goods such as French fries or potato wedges. Packs with variations in product thickness include chicken breasts and other fresh cuts of meat. Both scenarios produce an x-ray image with high levels of contrast.

The second type of application where dual energy x-ray is most suitable is where the likely contaminant in a food product is a low-density material, such as glass, plastic, rubber and calcified bone.

If a product application has one or both of these aspects, then a case can be made for dual energy x-ray. However, it is important to understand how this technology works. Here, the key concept is material discrimination.

How Dual Energy Works

Dual energy x-ray works by using high and low x-ray energy levels to discriminate between materials of different densities. A single generator produces the photon beam, which is then split into high and low energy levels either by a physical barrier before reaching the detector or electronically within the detector. This process allows the system to differentiate between the food product and any potential contaminants.

Rather than using machine learning, the system relies on proprietary software algorithms. These algorithms don’t just analyse the pixel’s grey level but instead assess the relationship between the grey levels of the same pixel in both the high and low energy images. This enables the system to remove the food product from the x-ray image, leaving behind any material identified by the second energy level, which is most likely a contaminant.

Photon Counting Technology

Photon counting represents a significant advancement in x-ray detection. A photon is a single particle of light, and in traditional silicon-based x-ray detectors, x-ray photons are initially converted into visible light by a phosphor screen. This visible light is then converted into an electrical signal by a silicon photodiode. While this process produces good x-ray images, some dispersion occurs during the light conversion, resulting in slightly “fuzzy” images.

With photon counting in advanced systems like DXD+, x-ray photons are directly converted into electrical signals using cadmium telluride (CdTe) crystals. When a photon above the energy bandwidth interacts with the CdTe crystal, it excites an electron from the valence band to the conduction band, creating an electron-hole pair. The energy absorbed by the crystal determines the energy of the excited electron in the conduction band, which produces the electrical signal. This direct conversion method eliminates the intermediate step of converting x-ray photons to visible light, resulting in sharper images compared to silicon-based detectors.

In silicon-based dual energy detectors, the x-ray spectrum is split using a physical barrier, such as a copper filter in HiGain+ DE. However, in DXD+, the spectrum is split electrically, using the signal obtained from the CdTe crystal. This electrical splitting is more precise and consistent, leading to clearer images and better material discrimination.

Photon counting also allows for a sharper separation of low and high energy components, which enhances image resolution, particularly in products with overlapping materials. CdTe detectors have a faster response time due to higher charge mobility, but because of how photon counting technology is applied, these detectors may have a slightly lower maximum speed compared to silicon detectors.

This image displays the x-ray spectrum emitted by an 84KV Beryllium generator, illustrating the energy range and highlighting the optimal split for a certain product. The graph provides insights into the distribution of energy levels, showcasing the characteristics of the emitted x-rays and how they are categorised for analysis.

Applications and Benefits of Photon Counting

Photon counting technology offers superior resolution and contrast, particularly in complex applications involving loose or overlapping products (e.g., frozen potato wedges or loose chicken breasts with bone).

Mettler-Toledo offers different technologies to meet these challenges, such as X52 (a conventional dual energy system) and photon counting dual energy systems like the X36, in the US and Europe, or the X35 in Asia. The X52 x-ray inspection system provides reliable contaminant detection with enhanced resolution, while the X36 and X35 systems take advantage of photon counting technology for even sharper imaging and greater detection accuracy.

Photon counting dual energy systems can detect smaller physical contaminants (as small as 0.2mm), which gives manufacturers an edge when competing for contracts that require strict detection standards. It’s the small gains that lead to big wins. Further, these advanced systems also help to reduce false rejects, leading to fewer wasted products and improved operational efficiency.

Advanced Detector Technology

The most advanced dual energy technology available today features an enhanced detector that collects detailed data about the product being inspected. In these systems, the enhanced detector uses cadmium telluride (CdTe), while standard dual energy systems use silicon (Si) detectors. CdTe-based detectors provide clearer, higher resolution images due to their ability to directly convert x-ray photons into electrical signals, reducing noise and improving image quality. When this is combined with sophisticated image analysis software and the algorithms mentioned above, the result is even clearer, higher resolution images that enable the best levels of physical contaminant detection possible today.

Best fit

Mettler-Toledo dual energy x-ray systems are capable of detecting significantly more difficult-to-find physical contaminants than single energy x-ray systems. The most common example would be poultry bones, which are often challenging to detect due to their low density. To be sure that a manufacturer’s application is best suited to dual energy x-ray manufacturers should look for a “Test Before You Invest” service. This is where a manufacturer can send product samples to be tested in real-life environmental conditions and receive a full analysis report of the findings.

The general rule of thumb is that dual energy is best suited to applications where some or all of these factors exist:

- The product being inspected is one with high contrast, caused by overlapping products or products with variable thicknesses.

- The expected physical contaminants are low density materials such as glass, rubber, plastic and calcified bone. It’s important to note that this is a relative measure; for instance, steel is considered high density, whereas plastic is classified as low density, as the density of plastic is only a fraction of that of steel.

- The packaging material used is low density, allowing low energy x-rays to pass through and inspect the product inside.

Improving the effectiveness of physical contaminant detection with dual energy x-ray that is optimised to the product application is clearly beneficial to food quality and consumer safety standards, but it also helps the food manufacturer’s business.

Consider, for example, the degree to which the sensitivity of a single energy x-ray system would have to be fine-tuned to detect very small contaminants such as 0.8mm pieces of stainless steel in packs of nuts. The sensitivity required for such an application would very likely cause many false rejects, which would result in a great deal of product throwaway. Turning down the sensitivity to reduce the false reject rate might mean that contaminated products pass undetected, leading to a product recall and damage to reputation.

Using dual energy x-ray would very likely enable the manufacturer to optimise detection around this application, without the resulting surge in false rejects and wasted products. In turn, this makes the business case for dual energy x-ray much stronger.

Balancing wants and needs

Dual energy x-ray systems, enhanced by advanced photon counting technology, represent the cutting edge of food safety and contaminant detection. By offering superior resolution and clearer images, they allow manufacturers to detect even the smallest physical contaminants, which is crucial for meeting stringent quality requirements. The increased sensitivity and material discrimination of these systems provide manufacturers with the tools to achieve the highest standards of safety without excessive false rejects.

In a competitive industry where safety and efficiency are top priorities, investing in these innovations not only improves detection but also reduces waste, enhances operational efficiency and strengthens a manufacturer’s position in securing new contracts. Ultimately, these small yet significant advances can lead to substantial rewards in both product safety and business performance.

For more information, please visit www.mt.com/xray-de-wp-pr or click here.

Read other recent news: https://industrial-compliance.co.uk/category/news/